Buyer's Guide Mechanics

WITH 3,006 REVIEWS

Click Here To Book Online Now

CLICK

To view local phone numbers

The inner workings of a garage door are just as important as the door itself. Ensuring the use of the appropriate spring, high quality rollers, hinges and tracks and maintaining those parts will greatly prolong the life of your door. Some elements may come as part of your door, while others may be upgrades.

The Interior

Below is what the interior of an average garage looks like with a torsion spring system. You will notice the different elements that make up the complete garage door system and help your door work and function properly.

Spring Systems

There are two types of garage door spring systems: extension and torsion. The spring system allows your garage door to move up and down, making it an important component of the overall garage door mechanics. The right spring system can depend on several factors, but ultimately your Door Designer will help you choose the best spring system for your door.

Extension Spring System

Extension spring systems use springs that stretch and retract to close and open your garage door. They extend along both horizontal tracks and are secured with a safety cable through the center.

While extension springs are less expensive than torsion systems, they require more parts and usually more maintenance. One advantage to this type of system is that each side of a spring system works independently so it can compensate for an uneven ground.

Older homes typically use extension systems because they have limited head room in the garage. Garage door openers were invented in 1926, but didn’t become popular until the 60s, so many garages weren’t built with them in mind. If you currently have an extension system, it’s recommended that you stick with that rather than reworking your whole garage spring system.

Torsion Spring System

Torsion springs are mounted on a torsion tube above your garage door horizontally and are wound up to create torque, or tension. As the door closes, cables attached to the bottom corners force the springs to wind up. When the door opens, the springs unwind and the tension transfers to lift the door open.

Torsion springs are generally safer than extension springs in terms of operation because they’re contained on a torsion tube. However, you should never try to wind, repair or replace a torsion spring by yourself. Because they are under such extreme tension, they can cause serious injury so always call a professional. They do tend to be a little more expensive.

Torsion systems work best if the ground in the garage door opening is completely level. You also need 12 inches above the door to mount the spring, so many times there is not room for a torsion system on an older home. Torsion systems are often recommended for heavier doors, but are required for all doors over 8 feet tall.

Tracks

Garage door tracks are located on both sides of the garage door and guide the door as it opens and closes. There are several different elements of the overall track system and what you need will depend on the type of door you choose and the dimensions of your existing garage.

Radius

The track radius is the curved part of your track that transfers the door from the vertical position to the horizontal position, or vice versa. The distance between the top of your door opening and the lowest point on your ceiling determines the maximum size of the radius for your track. Typically, the larger the radius, the smoother and more quietly your door will travel from open to close. Similar to a long winding road versus a road with a sharp switchback, the angle is approached more gradually and can be more easily managed.

The maximum size of your radius also defines how many horizontal panels that you can have in a door–which is especially important if you are interested in a 3 panel door which allows for larger windows.

What’s more, by choosing the largest possible radius, or upgrading to a high lift track, your door will be closer to the ceiling, giving you maximum headroom in the garage. Not sure which is right for you? Your Door Designer will give you guidance if this is something you are interested in.

The radius of your garage door track can impact everyday situations in your garage. If you have an elevated entryway door to your home in your garage, a radius that is too small could cause the track to run through the eye-line and be an eyesore, as well as potentially dangerous. You’ll also want to consider the radius if you use your garage for everyday car parking. A radius that is too small for the height of your vehicle could cause your trunk or car door to hit the track, motor rail or open garage resulting in damage.

Your Door Designer will do a proper measurement while at your home for a consultation but if you want to get a sense if a different radius is a possibility in your garage, you can try it yourself. Stand one foot back from the opening of your garage. While there, measure the vertical distance from the top opening of your garage door to the lowest point in your garage. The minimum headroom necessary is noted at the end of each track description below.

- Low Headroom Track: This is designed for manual doors or doors that have a garage door opener. It has a little bit of a turn at the front of the track to allow the top panel of the door to shut completely. Low headroom tracks can tend to be a little noisier than the other tracks because the top panel can slam as it’s closing. (Minimum difference: 3-5 inches)

- 10R: This is a better option than low headroom in terms of track, however it doesn’t work as smoothly as tracks with longer radiuses because it turns quicker and also limits the size of your panels. For this track to work properly, you don’t want to have a garage door with panels larger 21”. (Minimum difference: 9 inches)

- 12R: This is the most common size track we see in the Northeast. It offers decent headroom and the garage door functions well on a 12R track. For this track to operate properly, the door panels must be smaller than 32”. (Minimum difference: 11 inches)

- 15R: This radius size is the minimum required for a 3 panel garage door which supports larger windows. This type of track runs smooth because of the longer radius. (Minimum difference: 14 inches)

- 20R: This radius is more custom and can be more costly. The garage feels larger because the doors are up higher, however it requires a lot of headroom and the goalposts may have to be extended. Even with the extended headroom this radius offers, you can still use a regular garage door opener. (Minimum difference: 19 inches)

- 32R: This radius often makes the most sense if there is an elevated doorway in the garage used to enter the home. Standard track would run right through that doorway, creating an eyesore and possible safety hazard. A jackshaft opener and torsion spring system is required for this radius. If you have space to go higher, consider this radius. (Minimum difference: 31 inches)

- High Lift: High lift track is an extension between your vertical track and your horizontal track. If you use your garage as car storage with a car lift, you will most likely require a high lift track. This requires at least 12 feet of headroom in order to work. High lift track is constructed by extending the vertical track until it meets the horizontal track.

- Extra Feature - Powder Coated Track: Tracks, hinges, and brackets can be powder coated in virtually any color to blend into your garage ceiling and door. For those that have just built a home or take particular pride in their garage - this is a great enhancement to consider.

Woodwork

Woodwork refers to different elements of wood in your garage that can affect your garage door installation. Below we discuss two of the main sections in the interior of the garage that should be inspected before installation.

Goal Posts

This term describes the wood around your garage door frame inside your garage. The track and other garage door parts are mounted to the goal posts to keep the track secure and steady. It’s important that the woodwork around the garage door is in good condition and has no damage. If the bottom of the goal posts have rotted due to water damage, or the boards have split because the mounting holes for your current track were not pre-drilled, you will need to replace them.

Spending a small amount now to have your garage door installer replace the woodwork can help maintain the lifespan and safety of your door. Faulty woodwork can endanger the quality of your garage door materials and potentially any people, pets, or objects in the garage.

Headerboard

The header is the section of wall above your garage door opening that maintains the structural integrity of the opening, while a headerboard is a specific piece of lumber that creates a solid surface in the absence of a strong header area. Both are a mounting area for the motor rail and in some cases, torsion tube. The headerboard is far less likely to need to be replaced than a goal post as it isn’t exposed to water, however if it is cracked or not mounted securely, it may need to be replaced to ensure your garage door runs smoothly.

Good - Better - Best

Not all garage door parts are created equal. Below we lay out the different garage door parts in a Good, Better, Best comparison so you can make informed decisions about garage door mechanics.

Pulleys

Pulleys work together with the extension springs to lift the weight of the door. There are three different types of pulleys that homeowners will find in their garage.

- GOOD: A press fit pulley is two pieces of metal pressed together to form the working piece. It is likely to split over time due to the pressure from the cables.

- BETTER: A riveted steel pulley is similar to a press fit pulley with the addition of rivets for additional strength. Because it’s not one solid piece of equipment, the pulley can eventually split. It has bearings inside which will also eventually wear.

- BEST: A solid cast iron pulley has a sealed bearing and often lasts twice as long as a riveted pulley and won’t split as it is made from a single piece of iron.

Rollers

The rollers of your garage door move along the track as the door opens or closes. They can impact a door’s operational smoothness or noise level.

- GOOD: Steel rollers create a loud garage door because of the metal on metal contact with the track.

- BETTER: Plastic rollers are not as loud, but there is no bearing so there’s nothing to lubricate to help the door operate smoothly.

- BEST: Nylon rollers are quiet as they roll along the track. They have sealed bearings so they’ll never need lubrication.

Operating Cables

The placement of operating cables differs for extension systems and torsion systems, however the functions are the same: to provide the counterbalance strength to open and close the door. Extension operating cables run vertically on each side of the door, and horizontally to connect to the extension spring. Torsion operating cables run vertically down the length of the door. The weight and frequency of use of your door as well as the type of pulley used can shorten the lifespan of your cables.

- GOOD: Standard operating cables have 7 wires per strand and 7 strands per cable.

- BEST: Aircraft quality cables have almost 3x the amount of wires with 7 wires per strand and 19 strands per cable, increasing the durability and strength of the cables.

Center Bearings

Center bearings are the component of a torsion system that support the center of the torsion tube as it turns the torsion spring.

- GOOD: Plastic center bearings are a single donut-shaped component through which the torsion tube is placed. Because it is a fixed unit, the torsion tube may rub on the plastic center bearing and cause wear.

- BEST: Sealed steel center bearings are the same donut shaped piece of steel with a second piece of steel placed within the donut, supported by small sealed bearings for independent movement. The fluid movement of the second piece of steel eliminates friction on the tube for smoother operation.

Extension Springs

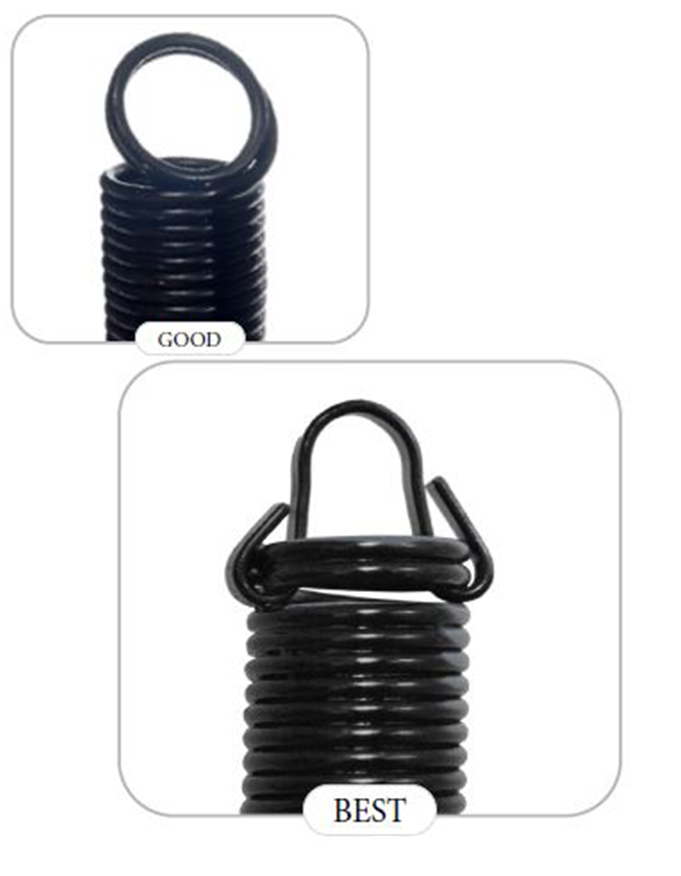

An extension spring system uses springs that stretch and retract to close and open your garage door. In an extension spring system, there are two different types of springs: double loop and shackle clip.

- GOOD: Double loop springs have a 2-layer loop at each end that connect to the eye hook and pulley.

- BEST: The shackle clip spring isn’t part of the coil as the clip is bent around the end of the spring, meaning it won’t be as susceptible to wear and tear and ultimately break off, as is possible with a double loop spring.

Torsion Springs

Torsion springs are mounted on a torsion tube above your garage door horizontally and are wound up to create torque, or tension. There are three different types of torsion springs: oil tempered, galvanized, and powder coated.

- GOOD: Oil tempered springs have the tendency to rust over time and can be noisy as the spring winds and unwinds.

- BETTER: Galvanized springs don’t rust but can corrode which leads to squeaking as the spring ages.

- BEST: Powdercoated springs will not rust or corrode because of the coating that protects them, leading to a longer lasting, quieter system.

Extension System Parts vs. Torsion System Parts

Have a question? Give us a call!

...Stay tuned for next week's "Garage Doors in Plain English"

Providing the information and resources you need to find the perfect garage door for your home and budget.

Garage Door Designer

Design your new garage door in 10 minutes and send for a free quote!

Providing the information and resources you need to find the perfect garage door for your home and budget.

Office: (760) 530-8540

225 S Civic Drive

Suite 1-2

Palm Springs, CA 92262

Licenses

CA State Contractors License809067

If you are looking for service in the Northern Los Angeles, Pomona, and Ontario areas, please visit:

precisiondoorla.com